For A 5kw Dc Motor The Number Of Slots Per Pole Should Be

We can see that each phase’s pole is divided into two coils which are equal to two solts/pole/phase, Hence, when you are allowed to have 24 turns/phase you will have 24 turns divided into two poles which are 12 turns /pole and 6 turns/slot. If you would please share your FEMM model with us that would be great! A dc motor develops a torque of 50Nm while rotating at 600rpm power developed by it is a four pole lap wound DC machine ha 48 slots on the armature with 8 conductors per slot the machine is driven at 1000 revolutions per minute and the useful flux per pole is 30mWb. So obviously the speed of an induction motor can be controlled by varying any of three factors namely supply frequency f, number of pole P or slip S. The main methods employed for speed control of induction motors are as follows: 1. Pole changing 2. Stator voltage control 3. Supply frequency control 4. Rotor resistance control 5.

White Papers and Application Notes

Modeling a Brushless DC Motor for an Advanced Actuation System using COMSOL Multiphysics® Software

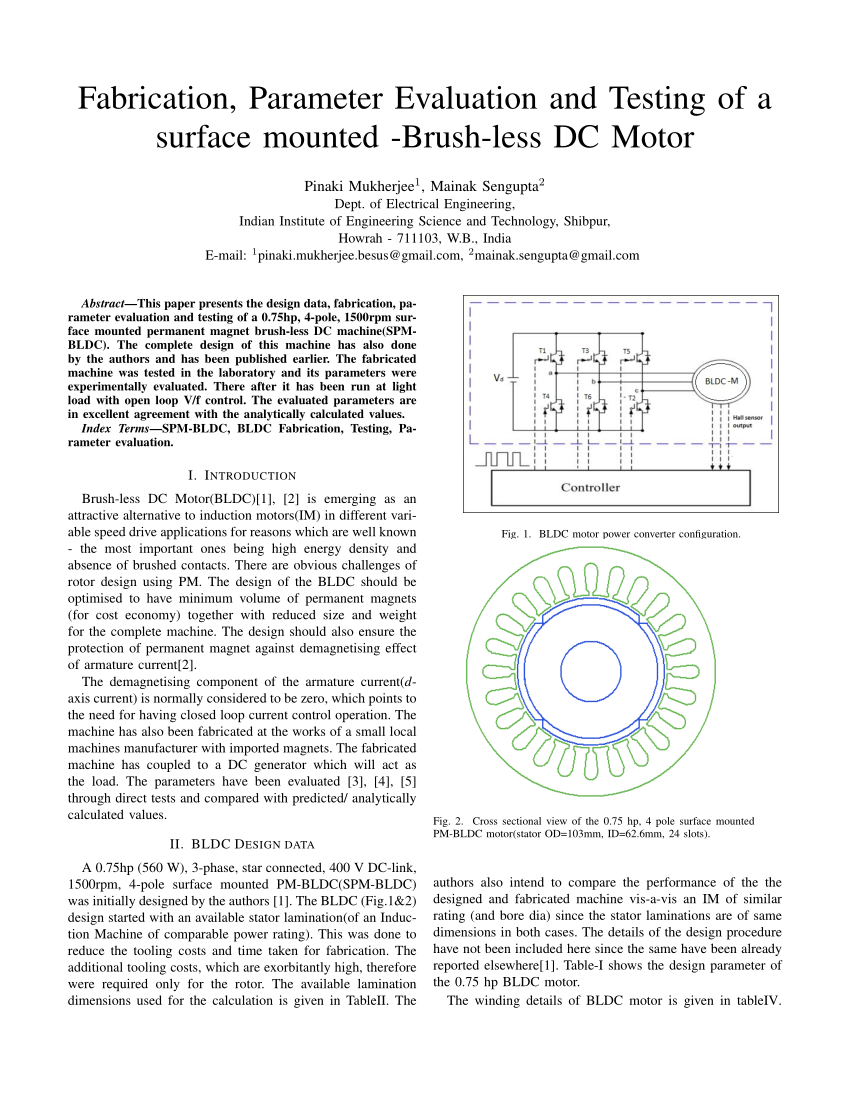

This paper presents the design and analysis of a high power radial flux Brushless DC motor for electro-mechanical actuation system. The motor is used for driving an electro-mechanical actuator of 20 ton capacity. Surface mounted, radially magnetized permanent magnet design is mostly preferred due to its ease of control, high efficiency and low maintenance. The motor under consideration is having four set of windings and four set of sensors for redundancy. The motor is rated for a maximum torque of 133Nm (@95A) per winding and a total torque of 532 Nm (@380 A) when all the windings are excited. The speed of the motor is 1850 rpm at a nominal voltage of 270V. The performance evaluation of radially magnetized permanent magnet motors for a three phase, 108 slots, 24 pole BLDC motor was carried out in finite element analysis software COMSOL Multiphysics® software. The number of poles has been chosen such that the motor mechanical envelop has been met and has high efficiency.

Since the motor is used for position control applications, the motor should have minimal cogging torque .In order to achieve this; fractional slot configuration has been chosen. Certain pole slot combinations are preferred. Here 108 slots have been chosen. COMSOL Multiphysics® software (finite element software) is used for computing electromagnetic torque, cogging torque, back EMF, magnetic flux density etc. Inductance calculation by analytical method is difficult and there is no direct relationship also. Moreover the material under consideration is non- linear in nature. So we have done it using Finite element simulation neglecting the end turn leakage inductance.

Inductance is found using energy method and virtual work method, as lower inductance may lead to high torque ripple which is undesirable in servo applications. The specification was achieved during design.

The motor is modeled using COMSOL Multiphysics® software and torque value was found out using Maxwell’s stress tensor method. The air gap flux density is also plotted. There is slight amount of saturation seen in stator core at higher currents in the torque profile, which is expected also. The non linear B-H curve of silicon steel was modeled in finite element software in order to study the saturation effect at high currents. Further reduction in saturation is possible by changing the material to iron cobalt for stator. Due to the presence of the slots, the air gap flux density waveform is having the ripples.

One of the issues faced during the assembly, was the insertion of rotor inside the stator body. The radial force between the stator and rotor handling was difficult. The magnetic pull due to rotor eccentricity was studied and evaluated using finite element method. A fixture is being designed, taking into consideration of radial force.

Download

For A 5kw Dc Motor The Number Of Slots Per Pole Should Bet

- ks_paper.pdf - 0.58MB

- ks_abstract.pdf - 0.02MB